Digital Barrier Verification System

A digital Barrier Verification System (BVS) provides continuous remote monitoring of lower barrier integrity when isolating the wellhead to conduct surface operations.

We deploy partner digital inwell technology with our retrievable bridge plugs to set a dual well barrier, then monitor pressure and temperature data from within the isolated zone to provide integrity assurance for the duration of operations.

This capability, deployed by our surface intervention system (SIS) and compact shear and seal valve, allows Unity to quickly perform safe, rigless interventions to inspect, test, maintain, repair and upgrade surface equipment.

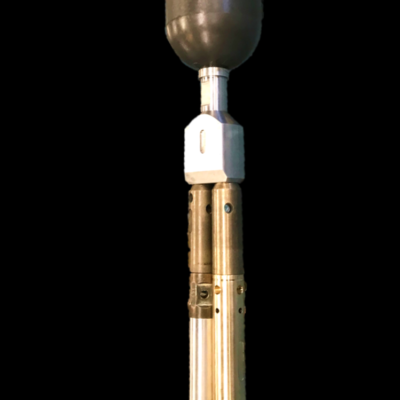

Our compact SIS would set two bridge plugs to depths of around 100 ft. A slimline BVS module is connected to the underside of the upper plug. Once deployed, pressure and temperature sensors continuously monitor the integrity of the isolated zone allowing us to confirm that the upper plug has been set successfully and the surface equipment is safe to access.

Downhole data is wirelessly transmitted to a non-intrusive (magnetically mounted) surface receiver at the wellhead, which interfaces with a read out panel and laptop located in a safe area. Both live and historic data can be monitored during operations to capture any subtle trends, de-risking operations. For long term monitoring, alerts can be set for specified data thresholds.

Benefits

The BVS systems we use are developed by trusted partners and have a strong track record in the field. These partnerships enhance Unity’s full-service capability for operators, allowing a wide range of rapid response intervention activities to be performed offline, concurrent to other site operations to improve efficiency.