Wells

well integrity in every step.

Experienced in all makes & models of wellhead equipment

100%

Unity is committed to a 50% reduction in carbon emissions by 2030

50%

As a trusted partner in offshore well services

30 Years

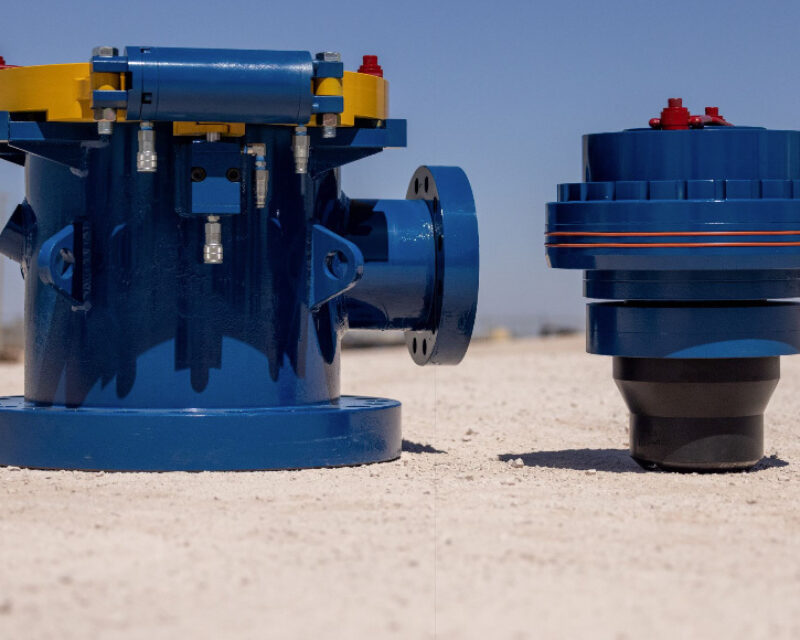

Keeping your wells online with surface and downhole integrity.

We're a fully integrated, international source of well integrity services and technology and an integral part of your team, providing lifetime maintenance, assurance and performance certainty.

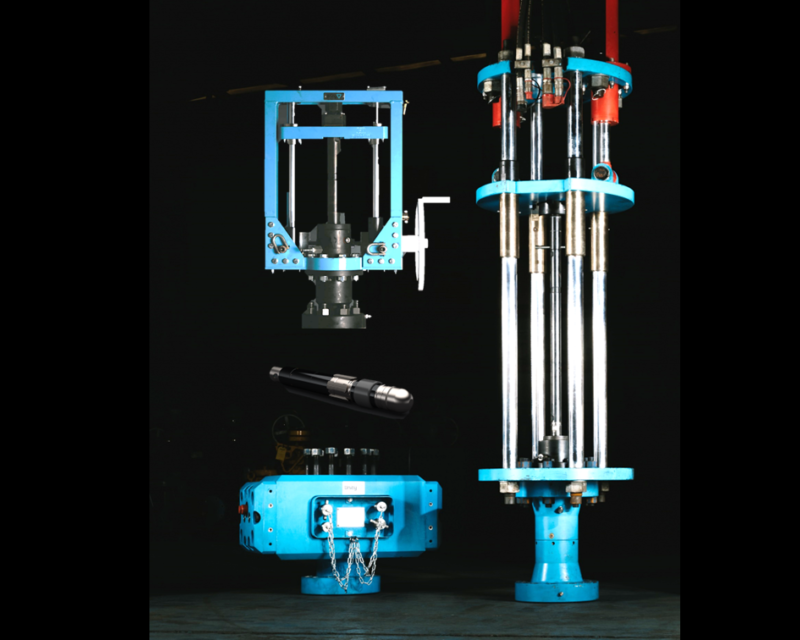

With a spread of innovative surface and thru-tubing solutions we solve challenges quickly, remediate failures and bring shut-in wells back to life.

Service Plans

Fully integrated, managed service plans reduce risk and ensure that your assets are well maintained for optimised operations.

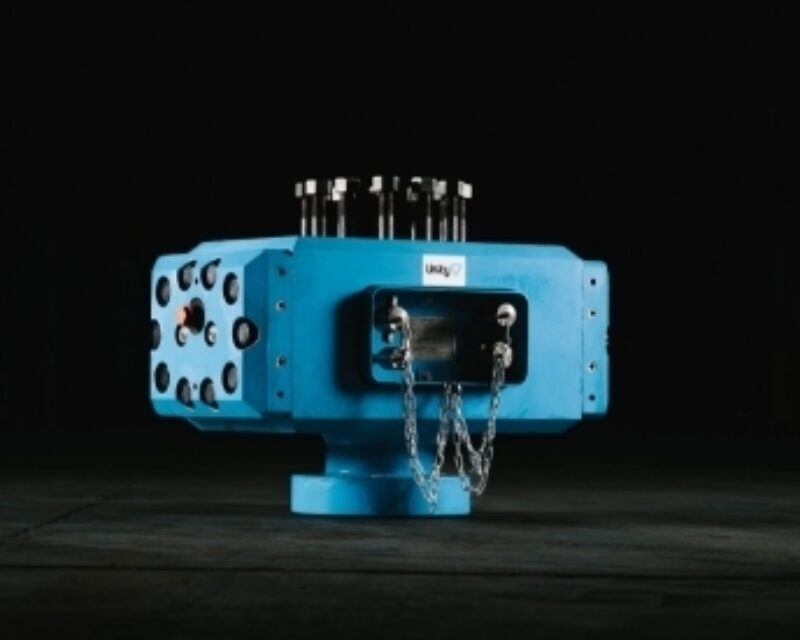

We are the expert caretaker of the critical access point to your well. We work with your teams to proactively schedule maintenance and remedial work around planned operations and shutdowns to minimise impact. Our turnaround times are fast, with onshore and offshore services working seamlessly to repair, refurbish and refit equipment with dramatically reduced lead-times.

Projects

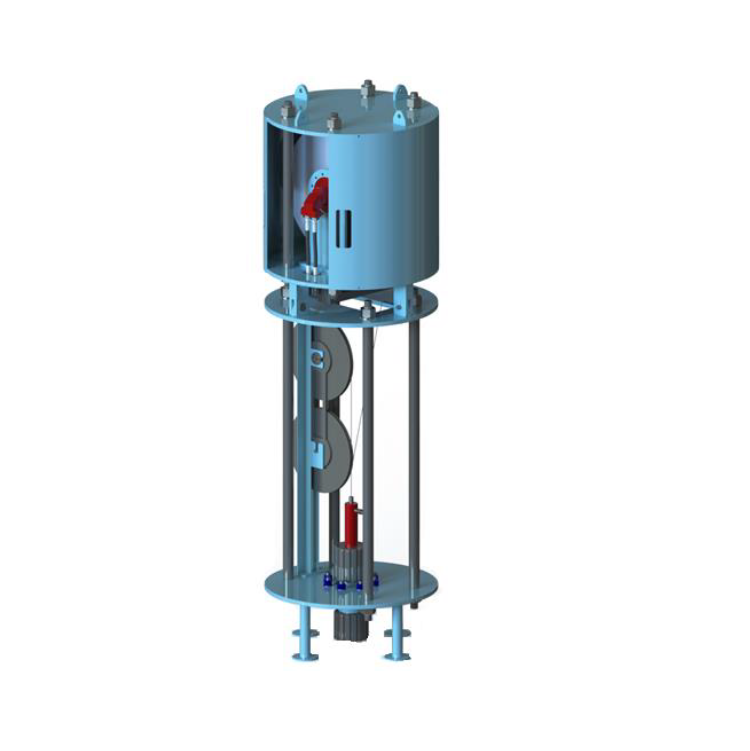

We work with clients around the world to deliver innovative engineering solutions for onshore, offshore, surface, subsurface, subsea and cross-sector well types.

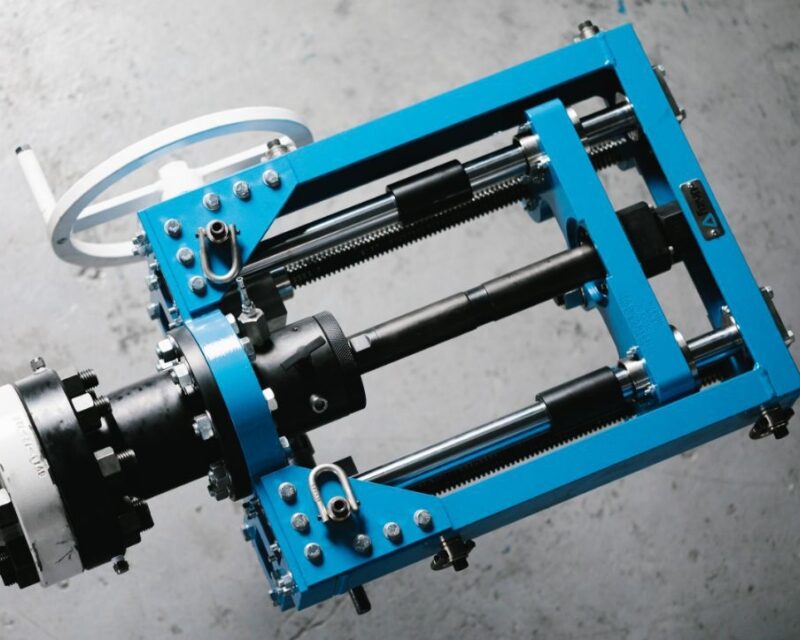

New solutions draw on our real world expertise and engineering know-how. Technology development projects have included stabilising conductors, rigless pressure testing tools for mudline wells and specialised intervention technology and tooling. Many solutions that begin as customer specific projects are developed to benefit the wider industry.

Confidence Assured

A 30 year track record of safeguarding asset performance and value.

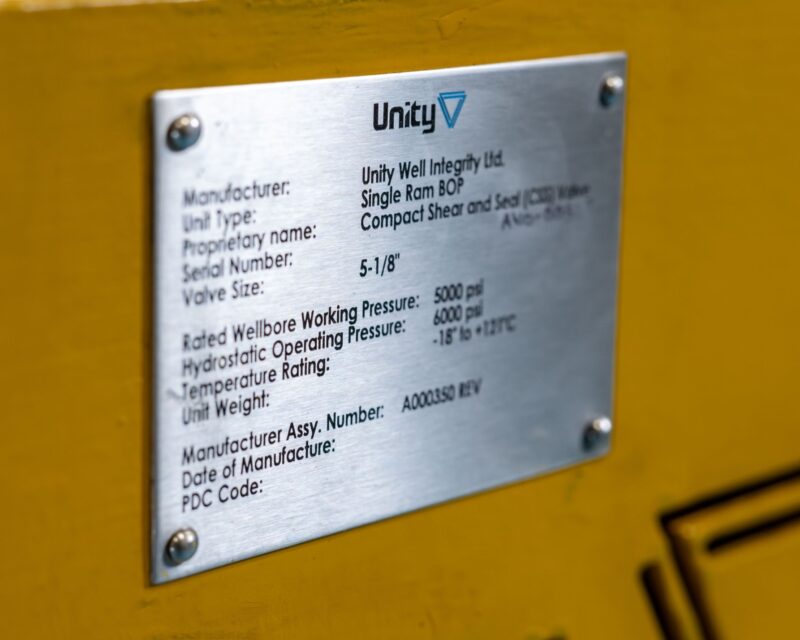

API Q1 Quality

API Q1 quality accreditation provides the highest assurance for maintenance, repair and upgrade; asset caretaking; product design, manufacture and rent.

Rapid Remediation and Production Restoration

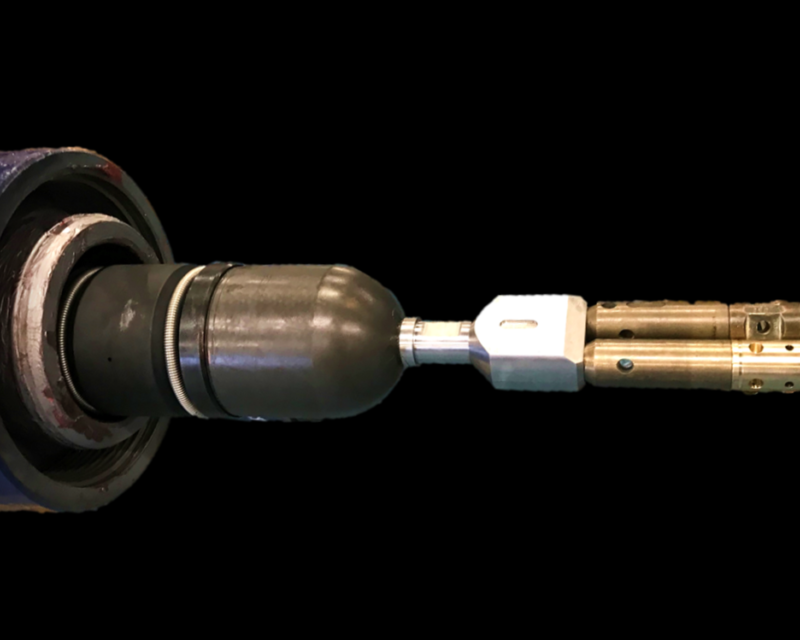

Production restoration is fast with a full end-to-end service including barrier setting, pressure control, repair and testing. Our wireline, slickline and coil conveyed inwell solutions, plus lightweight and rigless surface intervention technologies, solve complex challenges even in the most constrained environments.

Where wells have been shut-in due to the failure of components, OEM parts obsolescence or pressure decline, we'll restore production with rapid intervention and a large resource of universal products which offer significant savings and fast turnaround. We're a leading provider of additive manufactured components and our lightweight AM tree gates will solve seal integrity issues in low pressure wells, helping to bring them back online.

Latest News